Application

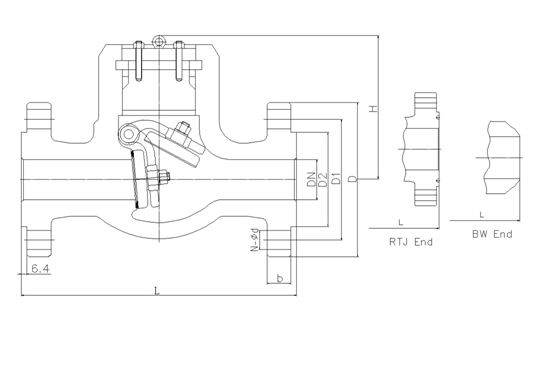

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:BS1868

Pressure Test:API598

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、CF3M 、CN7M、LC1

LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Class1500 High pressure check valve

NPS

in

2

2 1/2

3

4

5

6

8

10

12

14

16

d

mm

47

57

70

92

111

136

178

222

263

289

330

L(RF)

mm

368

419

470

546

673

705

832

991

1130

1257

1384

L(BW)

mm

368

419

470

546

673

705

832

991

1130

1257

1384

L(RTJ)

mm

371

422

473

549

676

711

841

1000

1146

1276

1407

d1

mm

92

105

127

157

186

216

270

324

381

413

470

d2

mm

165

190.5

203.2

241.3

292.1

317.5

393.7

482.6

571.5

635

704.8

D

mm

216

244

267

311

375

394

483

585

675

750

825

b

mm

38.5

41.5

48

54

73.5

83

92.9

108

124

133.5

146.5

n-Фd

mm

8-26

8-29

8-32

8-35

8-42

12-39

12-45

12-51

16-54

16-61

16-67

H

mm

210

240

303

340

380

430

500

590

660

710

820

|

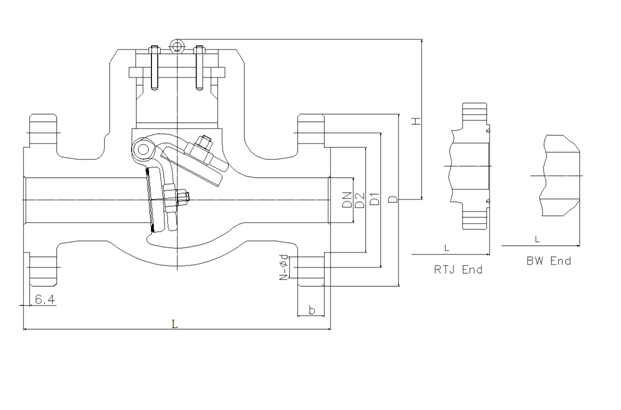

NPS |

in |

2 |

2 1/2 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

|

d |

mm |

38 |

47 |

57 |

73 |

92 |

111 |

146 |

184 |

219 |

|

L(RF) |

mm |

451 |

508 |

578 |

673 |

794 |

914 |

1022 |

1270 |

1422 |

|

L(BW) |

mm |

451 |

508 |

578 |

673 |

794 |

914 |

1022 |

1270 |

1422 |

|

L(RTJ) |

mm |

454 |

514 |

584 |

683 |

807 |

927 |

1038 |

1292 |

1445 |

|

d1 |

mm |

92 |

105 |

127 |

157 |

186 |

216 |

270 |

324 |

381 |

|

d2 |

mm |

171.4 |

196.8 |

228.6 |

273 |

323.8 |

368.3 |

438.1 |

539.7 |

619.1 |

|

D |

mm |

235 |

267 |

305 |

356 |

419 |

483 |

550 |

675 |

760 |

|

b |

mm |

51 |

57.5 |

67 |

76.5 |

92.5 |

108 |

127 |

165.5 |

184.5 |

|

n-Фd |

mm |

8-29 |

8-32 |

8-35 |

8-42 |

8-48 |

8-54 |

12-54 |

12-67 |

12-74 |

|

H |

mm |

230 |

260 |

330 |

370 |

410 |

460 |

530 |

620 |

690 |

API Trim NO. Table

|

No of internal parts |

Seat ring or body |

Gate、disc 、ball or body |

Stem |

No of internal parts |

Seat ring or body |

Gate、disc 、ball or body |

Stem |

|

|

01 |

13Cr |

13Cr |

13Cr |

31 |

STELLITE |

321SS |

321SS |

|

|

02 |

304SS |

304SS |

304SS |

32 |

STELLITE |

STELLITE |

321SS |

|

|

03 |

310SS |

310SS |

310SS |

33 |

347SS |

347SS |

347SS |

|

|

04 |

HARD 13Cr |

HARD 13Cr |

13Cr |

34 |

STELLITE |

347SS |

347SS |

|

|

05 |

STELLITE |

STELLITE |

13Cr |

35 |

NICKEL ALLOY |

13Cr |

13Cr |

|

|

06 |

Cu-Ni |

13Cr |

13Cr |

36 |

A105/PTFE |

A105+ENP |

A105+ENP |

|

|

07 |

13Cr |

HARD 13Cr |

13Cr |

37 |

A105/PTFE |

WCB+ENP |

A105+ENP |

|

|

08 |

STELLITE |

13Cr |

13Cr |

38 |

13Cr/PTFE |

13Cr |

13Cr |

|

|

09 |

Cu-Ni |

Cu-Ni |

Cu-Ni |

39 |

304SS/PTFE |

304SS |

304SS |

|

|

10 |

316SS |

316SS |

316SS |

40 |

316SS/PTFE |

316SS |

316SS |

|

|

11 |

Cu-Ni |

STELLITE |

Cu-Ni |

41 |

A105/RPTFE |

A105+ENP |

A105+ENP |

|

|

12 |

STELLITE |

316SS |

316SS |

42 |

A105/RPTFE |

WCB+ENP |

A105+ENP |

|

|

13 |

ALLOY 20 |

ALLOY 20 |

ALLOY 20 |

43 |

13Cr/RPTFE |

13Cr |

13Cr |

|

|

14 |

STELLITE |

ALLOY 20 |

ALLOY 20 |

44 |

304SS/RPTFE |

304SS |

304SS |

|

|

15 |

STELLITE |

STELLITE |

304SS |

45 |

316SS/RPTFE |

316SS |

316SS |

|

|

16 |

STELLITE |

STELLITE |

316SS |

46 |

A105/NYLON |

A105+ENP |

A105+ENP |

|

|

17 |

STELLITE |

STELLITE |

347SS |

47 |

A105/NYLON |

WCB+ENP |

A105+ENP |

|

|

18 |

STELLITE |

STELLITE |

ALLOY 20 |

48 |

A105/NYLON |

304SS |

304SS |

|

|

19 |

MONEL |

MONEL |

MONEL |

49 |

A105/NYLON |

316SS |

316SS |

|

|

20 |

BRONZE |

BRONZE |

13Cr |

50 |

13Cr/NYLON |

13Cr |

13Cr |

|

|

21 |

HASTELLOY B |

HASTELLOY B |

HASTELLOY B |

51 |

304SS/NYLON |

304SS |

304SS |

|

|

22 |

|

HASTELLOY C |

HASTELLOY C |

52 |

316SS/NYLON |

316SS |

316SS |

|

|

23 |

STELLITE |

304SS |

304SS |

53 |

A105/PEEK |

A105+ENP |

A105+ENP |

|

|

24 |

304LSS |

304LSS |

304LSS |

54 |

A105/PEEK |

WCB+ENP |

A105+ENP |

|

|

25 |

STELLITE |

304LSS |

304LSS |

55 |

13Cr/PEEK |

13Cr |

13Cr |

|

|

26 |

STELLITE |

STELLITE |

304LSS |

56 |

304SS/PEEK |

304SS |

304SS |

|

|

27 |

316LSS |

316LSS |

316LSS |

57 |

316SS/PEEK |

316SS |

316SS |

|

|

28 |

STELLITE |

316LSS |

316LSS |

|

|

|

|

|

|

29 |

STELLITE |

STELLITE |

316LSS |

|

|

|

||

|

30 |

321SS |

321SS |

321SS |

|

|

|

|

|

Note:please indicate it directly in the order for the internal part’smaterial uncovered in the table

Welcome to our website! Please feel free to send us your inquiry in detail, we will reply you as soon as possible.

English

English España

España

Flowork-valve

Flowork-valve E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link