产品描述

Pressure Seal Gate Valves can adjust the pressure of sealing ring automatically to fit with the different inner pressures in the pipeline. This type of Gate valves is usually used in high temperature and high pressure operating conditions.

Application

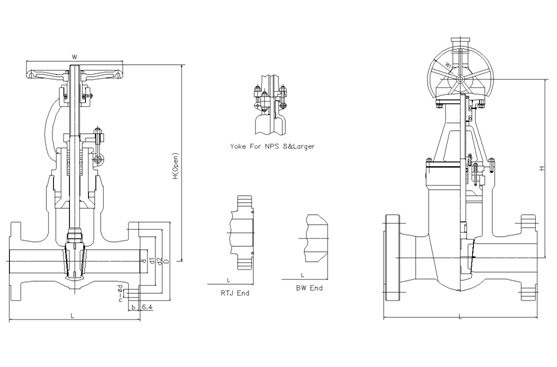

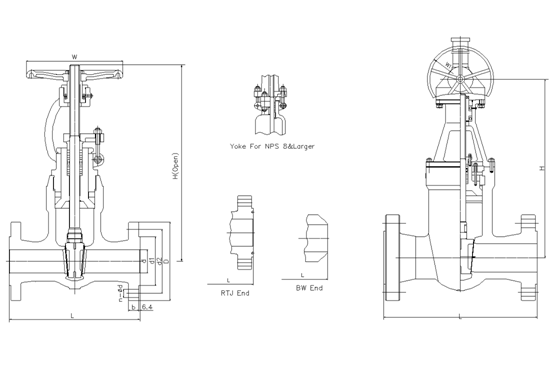

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 600

Pressure Test:API 598

Main material: WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1、LC2、LC3、LCB、LCC、Monel、 20# Alloys、4A、5A、C95800、C95500, ect.

Class1500 Pressure Seal Gate Valve

|

NPS |

in |

2 |

2 1/2 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

|

d |

mm |

47 |

57 |

70 |

92 |

111 |

136 |

178 |

222 |

263 |

289 |

330 |

|

L(RF) |

mm |

368 |

419 |

470 |

546 |

673 |

705 |

832 |

991 |

1130 |

1257 |

1384 |

|

L(BW) |

mm |

368 |

419 |

470 |

546 |

673 |

705 |

832 |

991 |

1130 |

1257 |

1384 |

|

L(RTJ) |

mm |

371 |

422 |

473 |

549 |

676 |

711 |

841 |

1000 |

1146 |

1276 |

1407 |

|

d1 |

mm |

92 |

105 |

127 |

157 |

186 |

216 |

270 |

324 |

381 |

413 |

470 |

|

d2 |

mm |

165 |

190.5 |

203.2 |

241.3 |

292.1 |

317.5 |

393.7 |

482.6 |

571.5 |

635 |

704.8 |

|

D |

mm |

216 |

244 |

267 |

311 |

375 |

394 |

483 |

585 |

675 |

750 |

825 |

|

b |

mm |

38.5 |

41.5 |

48 |

54 |

73.5 |

83 |

92.9 |

108 |

124 |

133.5 |

146.5 |

|

n-Фd |

mm |

8-26 |

8-29 |

8-32 |

8-35 |

8-42 |

12-39 |

12-45 |

12-51 |

16-54 |

16-61 |

16-67 |

|

H |

mm |

510 |

560 |

620 |

728 |

870 |

1000 |

1130 |

1360 |

|

|

|

|

H1 |

mm |

|

|

670 |

770 |

920 |

1070 |

1180 |

1410 |

1620 |

2020 |

2180 |

|

W |

mm |

280 |

300 |

350 |

400 |

450 |

500 |

750 |

900 |

|

|

|

|

W1 |

mm |

|

|

310 |

310 |

310 |

460 |

460 |

600 |

600 |

600 |

600 |

|

NPS |

in |

2 |

2 1/2 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

|

d |

mm |

38 |

47 |

57 |

73 |

92 |

111 |

146 |

184 |

219 |

|

L(RF) |

mm |

451 |

508 |

578 |

673 |

794 |

914 |

1022 |

1270 |

1422 |

|

L(BW) |

mm |

451 |

508 |

578 |

673 |

794 |

914 |

1022 |

1270 |

1422 |

|

L(RTJ) |

mm |

454 |

514 |

584 |

683 |

807 |

927 |

1038 |

1292 |

1445 |

|

d1 |

mm |

92 |

105 |

127 |

157 |

186 |

216 |

270 |

324 |

381 |

|

d2 |

mm |

171.4 |

196.8 |

228.6 |

273 |

323.8 |

368.3 |

438.1 |

539.7 |

619.1 |

|

D |

mm |

235 |

267 |

305 |

356 |

419 |

483 |

550 |

675 |

760 |

|

b |

mm |

51 |

57.5 |

67 |

76.5 |

92.5 |

108 |

127 |

165.5 |

184.5 |

|

n-Фd |

mm |

8-29 |

8-32 |

8-35 |

8-42 |

8-48 |

8-54 |

12-54 |

12-67 |

12-74 |

|

H |

mm |

530 |

580 |

650 |

750 |

900 |

1040 |

1150 |

1400 |

|

|

H1 |

mm |

580 |

630 |

700 |

800 |

960 |

1100 |

1200 |

1460 |

1660 |

|

W |

mm |

280 |

300 |

350 |

400 |

500 |

600 |

750 |

900 |

|

|

W1 |

mm |

310 |

310 |

310 |

310 |

460 |

460 |

460 |

600 |

600 |

API Trim NO. Table

|

No of internal parts |

Seat ring or body |

Gate、disc 、ball or body |

Stem |

No of internal parts |

Seat ring or body |

Gate、disc 、ball or body |

Stem |

|

|

01 |

13Cr |

13Cr |

13Cr |

31 |

STELLITE |

321SS |

321SS |

|

|

02 |

304SS |

304SS |

304SS |

32 |

STELLITE |

STELLITE |

321SS |

|

|

03 |

310SS |

310SS |

310SS |

33 |

347SS |

347SS |

347SS |

|

|

04 |

HARD 13Cr |

HARD 13Cr |

13Cr |

34 |

STELLITE |

347SS |

347SS |

|

|

05 |

STELLITE |

STELLITE |

13Cr |

35 |

NICKEL ALLOY |

13Cr |

13Cr |

|

|

06 |

Cu-Ni |

13Cr |

13Cr |

36 |

A105/PTFE |

A105+ENP |

A105+ENP |

|

|

07 |

13Cr |

HARD 13Cr |

13Cr |

37 |

A105/PTFE |

WCB+ENP |

A105+ENP |

|

|

08 |

STELLITE |

13Cr |

13Cr |

38 |

13Cr/PTFE |

13Cr |

13Cr |

|

|

09 |

Cu-Ni |

Cu-Ni |

Cu-Ni |

39 |

304SS/PTFE |

304SS |

304SS |

|

|

10 |

316SS |

316SS |

316SS |

40 |

316SS/PTFE |

316SS |

316SS |

|

|

11 |

Cu-Ni |

STELLITE |

Cu-Ni |

41 |

A105/RPTFE |

A105+ENP |

A105+ENP |

|

|

12 |

STELLITE |

316SS |

316SS |

42 |

A105/RPTFE |

WCB+ENP |

A105+ENP |

|

|

13 |

ALLOY 20 |

ALLOY 20 |

ALLOY 20 |

43 |

13Cr/RPTFE |

13Cr |

13Cr |

|

|

14 |

STELLITE |

ALLOY 20 |

ALLOY 20 |

44 |

304SS/RPTFE |

304SS |

304SS |

|

|

15 |

STELLITE |

STELLITE |

304SS |

45 |

316SS/RPTFE |

316SS |

316SS |

|

|

16 |

STELLITE |

STELLITE |

316SS |

46 |

A105/NYLON |

A105+ENP |

A105+ENP |

|

|

17 |

STELLITE |

STELLITE |

347SS |

47 |

A105/NYLON |

WCB+ENP |

A105+ENP |

|

|

18 |

STELLITE |

STELLITE |

ALLOY 20 |

48 |

A105/NYLON |

304SS |

304SS |

|

|

19 |

MONEL |

MONEL |

MONEL |

49 |

A105/NYLON |

316SS |

316SS |

|

|

20 |

BRONZE |

BRONZE |

13Cr |

50 |

13Cr/NYLON |

13Cr |

13Cr |

|

|

21 |

HASTELLOY B |

HASTELLOY B |

HASTELLOY B |

51 |

304SS/NYLON |

304SS |

304SS |

|

|

22 |

|

HASTELLOY C |

HASTELLOY C |

52 |

316SS/NYLON |

316SS |

316SS |

|

|

23 |

STELLITE |

304SS |

304SS |

53 |

A105/PEEK |

A105+ENP |

A105+ENP |

|

|

24 |

304LSS |

304LSS |

304LSS |

54 |

A105/PEEK |

WCB+ENP |

A105+ENP |

|

|

25 |

STELLITE |

304LSS |

304LSS |

55 |

13Cr/PEEK |

13Cr |

13Cr |

|

|

26 |

STELLITE |

STELLITE |

304LSS |

56 |

304SS/PEEK |

304SS |

304SS |

|

|

27 |

316LSS |

316LSS |

316LSS |

57 |

316SS/PEEK |

316SS |

316SS |

|

|

28 |

STELLITE |

316LSS |

316LSS |

|

|

|

|

|

|

29 |

STELLITE |

STELLITE |

316LSS |

|

|

|

||

|

30 |

321SS |

321SS |

321SS |

|

|

|

|

|

Note:please indicate it directly in the order for the internal part’smaterial uncovered in the table

¡Bienvenido a nuestro sitio web! No dude en enviarnos su consulta en detalle, le responderemos lo antes posible.

English

English España

España

Flowork-valve

Flowork-valve E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link